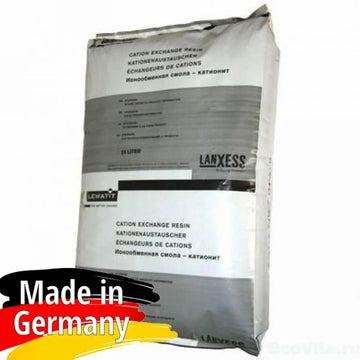

Softening Resin LEWATIT S1567

-

Estimated Delivery:Jan 18 - Jan 22

-

Next Day Dispatch

Softening Resin LEWATIT S1567

LEWATIT® S1567, Premium Food Grade Softening Ion Exchange Resin

- Premium Food Grade Softening Ion Exchange Resin, Highly Chlorine-Resistant, Made Using Solvent-Free Production Process.

- 25 L Bag.

Lewatit® S1567 is a monodisperse cation exchanger made using a solvent-free production process. It has been developed for the softening of both potable water in household installations (e.g., softening units equipped with cartridges) and raw water used in industrial plants.

It is very economical due to the product’s durability and long life. The monodisperse ion exchange matrix is very stable both chemically and mechanically, and its uniformity ensures a homogenous flow through the filter. This minimizes rinse water requirements and maximizes utilization of the regeneration.

The monodisperse beads are chemically and osmotically very stable, and they can effectively be disinfected for the drinking water processing. The optimised kinetics lead to an increased operating capacity compared to ion exchange resins with heterodisperse bead size distribution.

Lewatit S 1567 is especially applicable for:

- Softening in special systems with regular disinfection.

- Water softening applications where media bed disinfection is required (Hospitals, Pharmaceutical, Food industry).

- Softening of drinking water.

- Residential, commercial and industrial water softeners.

Long service life and longevity, Low salt consumption, Chlorine tolerance.

Advantages:

- Solvent-free sulfonation.

- Simple and improved disinfection.

- Monodispersity.

- Excellent chemical and mechanical stabilities.

- Very low content of fines.

- High capacity.

Lewatit S1567 features:

- High exchange flow rates during regeneration and loading.

- a good utilisation of the total capacity.

- a low demand for rinse water.

- Homogeneous throughput of regenerants, water and solutions; therefore a homogeneous working zone.

- Nearly linear pressure drop gradient for the whole bed depth; therefore operation with higher bed depth is poss.

Compared with other resins, Lewatit resins out perform all other resins in respect of service life and longevity because it has a reduced salt consumption and improved chlorine tolerance.

Manufacturer: Lanxess, Made in Germany.

Packaging: 25L Bag.

Download

Technical Data Sheet

We deliver Australia wide.

This item is not eligible for free shipping, We deliver Australia wide.

Contact us for pricing, shipping cost and availability. info@waterfilter.net.au

Softening Resin

Softening Resin is a strong cation exchange resin supplied in its sodium form, it is normally used to soften hard water. Water hardness is usually calculated as Ca2+ and Mg2+.

Softener Resin exchanges the hardness minerals (calcium and magnesium) dissolved in water for sodium. This soft mineral is contained on the softener resin beads and does not build up on surfaces as scale deposits.

It is regenerated with a brine solution (salt).

Discover more in our FAQ

What types of industrial water treatment products do you offer?

We offer a comprehensive range of industrial water treatment solutions, including:

Filtration Systems – Effectively removes sediment, chlorine, and other impurities to enhance water purity and system longevity.

Reverse Osmosis Membranes – High-performance purification technology that eliminates dissolved solids, contaminants, and impurities for ultra-pure water.

Membrane Housings – Durable, high-pressure enclosures engineered to protect and optimize the performance of RO membranes.

Filter Cartridges – Precision-engineered sediment, carbon, and specialty filters designed to target specific contaminants for enhanced water treatment efficiency.

Chemical Dosing Systems – Precise chemical treatment for water.

Media FRP Pressure Vessels – High-pressure tanks for filtration media.

Ion Exchange Resins – Softening and demineralization solutions.

Water Instruments – pH meters, conductivity meters, and TDS testers.

Rotameter Flow Meters – Accurate flow measurement devices.

Watermaker Parts – Spare parts for marine and industrial watermakers.

Water Quality Test Kits – Portable and lab testing solutions.

How do I know which product is right for my application?

Choosing the right product depends on:

Water quality parameters (TDS, pH, hardness, contaminants)

Flow rate and pressure requirements

Industry-specific needs (food processing, pharmaceuticals, HVAC, etc.)

If you’re unsure, our technical support team can help you select the best solution.

Do you offer bulk pricing for large industrial orders?

Yes! We provide bulk discounts and custom pricing for high-volume orders. Contact us for a personalized quote.

How long does shipping take?

Shipping times depend on location and stock availability. Standard delivery is 3–7 business days for most regions. Expedited shipping options are available upon request.

What is your return policy?

We offer a 14-day return policy from the date of delivery. If you are not completely satisfied with your purchase, you can return the item for a refund or exchange, provided it meets our return conditions.

What happens if I receive a damaged or incorrect item?

If your item arrives damaged or you receive the wrong product, please contact us immediately at support@waterfilter.net.au with photos and your order number. We will send a replacement or issue a refund as per our return policy..

How long does shipping take?

Shipping times depend on location and stock availability. Standard delivery is 3–7 business days for most regions.

Expedited shipping options are available upon request.

Do you ship internationally?

Yes, we offer international shipping for most of our industrial water treatment products. Contact us for custom shipping quotes and lead times.